pat testing

In accordance with the Electricity at Work Regulations (1989), any electrical equipment that as the potential to cause injury must be maintained in a safe condition. PAT testing is an expected part of every employer's safety environment. There are a number of things to consider when deciding on the frequency of PAT testing. These are covered in the 5th Edition of the IET Code of Practice risk assessment. There are 8 factors you should take into account to determine the test interval, which should be chosen, so far as reasonably practicable, to prevent danger.

BE IN THE KNOW!

How often do you need to have a PAT test?

As the duty holder, its your responsibility to ensure your electrical appliances are safe, our recommendation would be to have full PAT inspection on annually basis.

As soon as your appliances are compliant, you wont have to worry about forgetting to get them tested again. Our free reminder service will let you know when its time to get in touch to book in your PAT testing.

Is PAT testing a legal requirement?

The electricity at work regulations 1989 make it your responsibility to make sure all your electrical equipment is safe to use. So you should regularly inspect, test and maintain electrical appliances to make sure they’re compliant. If you don’t do this, you could be putting yourself, your employees, and your business at risk.

What is tested in a PAT test?

we carry out a number of inspections as part of our PAT tests:

1 - User Checks

This informs the use or any potential danger signs, an appliance can fail on this check i.e a frayed cable can be marked as not safe to use.

2 - Formal Visual Inspection

This is a simple process of visually inspecting all of the appliance for damage, exposed wires, missing parts. we also check inside the plug to make sure all wires are secure and the correct fuse is fitted into the appliance.

3 - Combined Inspections and Testing

This is the main test, that involves using the PAT testing machine. This determines if the device is electrically safe to use.

What needs to be PAT tested?

Any electrical appliance that has a plug needs to be PAT tested.

This may include any of the following:

Hand held equipment, stationary equipment, IT equipment, movable equipment under 18kg, fixed equipment i.e hand dryers.

We carry out the following tests

Class 1 Test: Checking earth continuity and insulation resistance

Class 2 Test: Checking insulation resistance

Class 3 Test: Formal visual inspection of low voltage appliances

Microwave Emission Test: Checking levels of radiation that are emitted from the machine to follow recommended guidelines.

Why Choose Safe Spark Group LTD for your pat testing

City & Guilds 2377 Qualified Engineers

Fully Insured & All Engineers are Enhanced DBS Checked

Competitive Prices & Flexible Service

Out of Hours & Weekend Testing

Asset Management Report & Completion Certificate

Free Minor Repairs i.e. Fuses, Plug Replacements

All Documents Sent to You Within 48 Hours After Completion

Minimal Disruption to Your Business

Free Reminder Service, Letting You Know When Your Retest is Due

EICR INSPECTION AND TESTING

SafeSpark Group is a fixed wire testing specialist, providing electrical inspection and testing services to clients throughout the UK. We offer a comprehensive range of services, whether you require fixed wire testing on any commercial or industrial electrical installations or a commercial electrical installation condition report (EICR).

When was the last time your business had a fixed wire test carried out?

The frequency of fixed wire testing will depend on a variety of factors, such as the type of electrical installation, its age and condition, and the use to which it is put. However, as a general rule, fixed wire testing should be carried out at least every five years.

We pride ourselves on our high standards of workmanship and customer service

Our team of skilled engineers is fully trained and qualified to assess all fixed electrical equipment and installations. Whether you need us to carry out a one-off fixed wire test or you’re looking for a long-term partner for your business, we’re here to help.

Our Testing Equipment

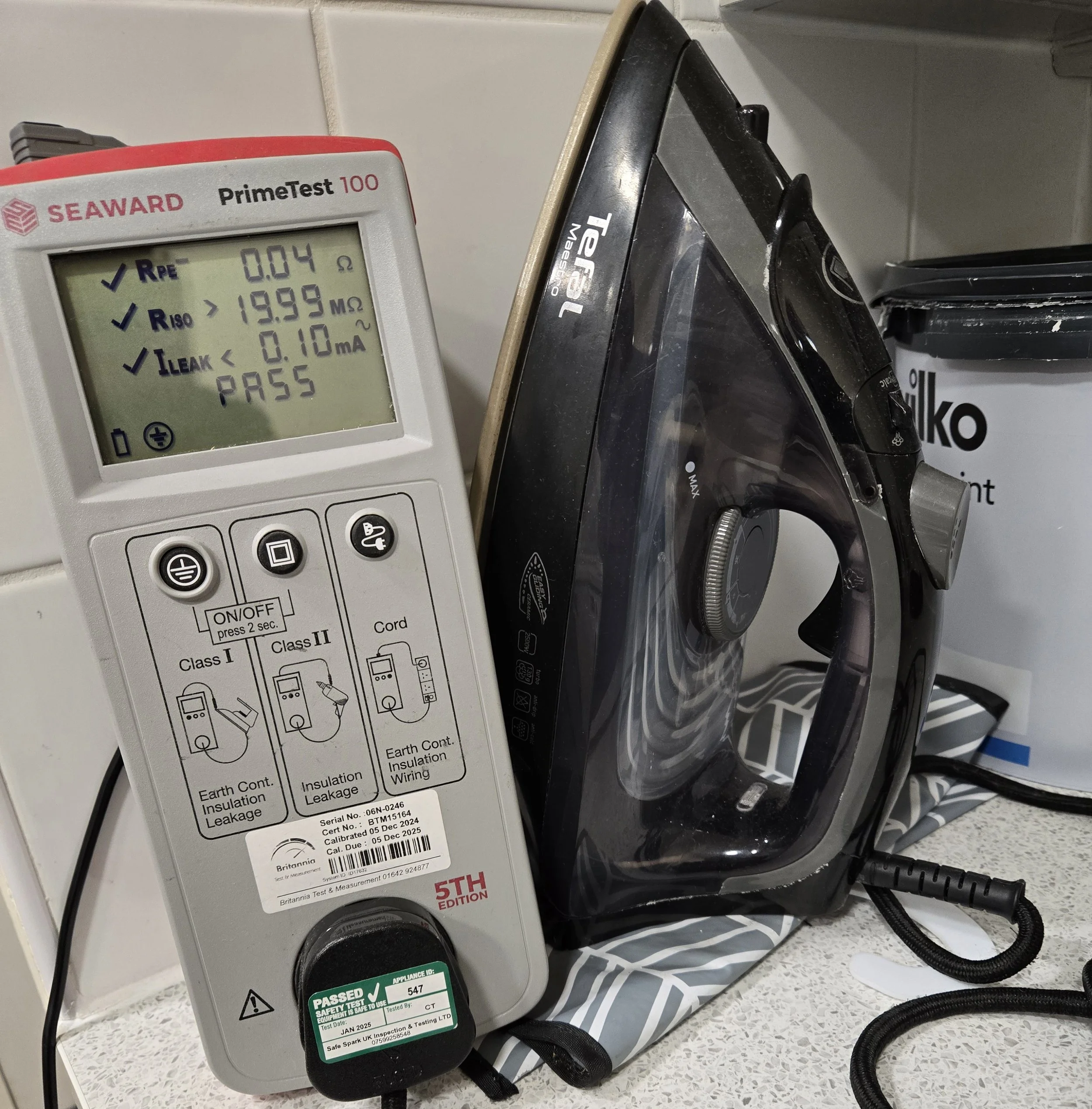

Seaward Prime Test 100

Seaward Apollo 600

At SAFE SPARK GROUP LTD, we use the most up-to-date testing equipment to ensure all tests carried out are safe, reliable, and meet the latest safety regulations and requirements. Our certified professionals conduct thorough inspections, identifying potential hazards and ensuring compliance with industry standards. Regular PAT testing not only protects your employees and customers but also safeguards your business from legal liabilities. Trust SAFE SPARKS GROUP for comprehensive safety solutions tailored to your needs. Your safety is our priority.

SAFETY TEST LABELS

SAFE SPARK GROUP LTD adheres strictly to the IET Code of Practice 5th Edition, ensuring the highest standards of safety and compliance in all our services. It is important to note that our labels do not include a retest date, reflecting the latest guidelines and best practices in the industry.

Furthermore, if a formal visual inspection is performed on an appliance, we clearly indicate this with a blue label. This practice not only enhances transparency but also provides reassurance to our customers that their equipment has been thoroughly assessed. Detailed records of such inspections are included in your report for easy reference. Your safety and compliance are our top priorities.

Why PAT Testing Important?

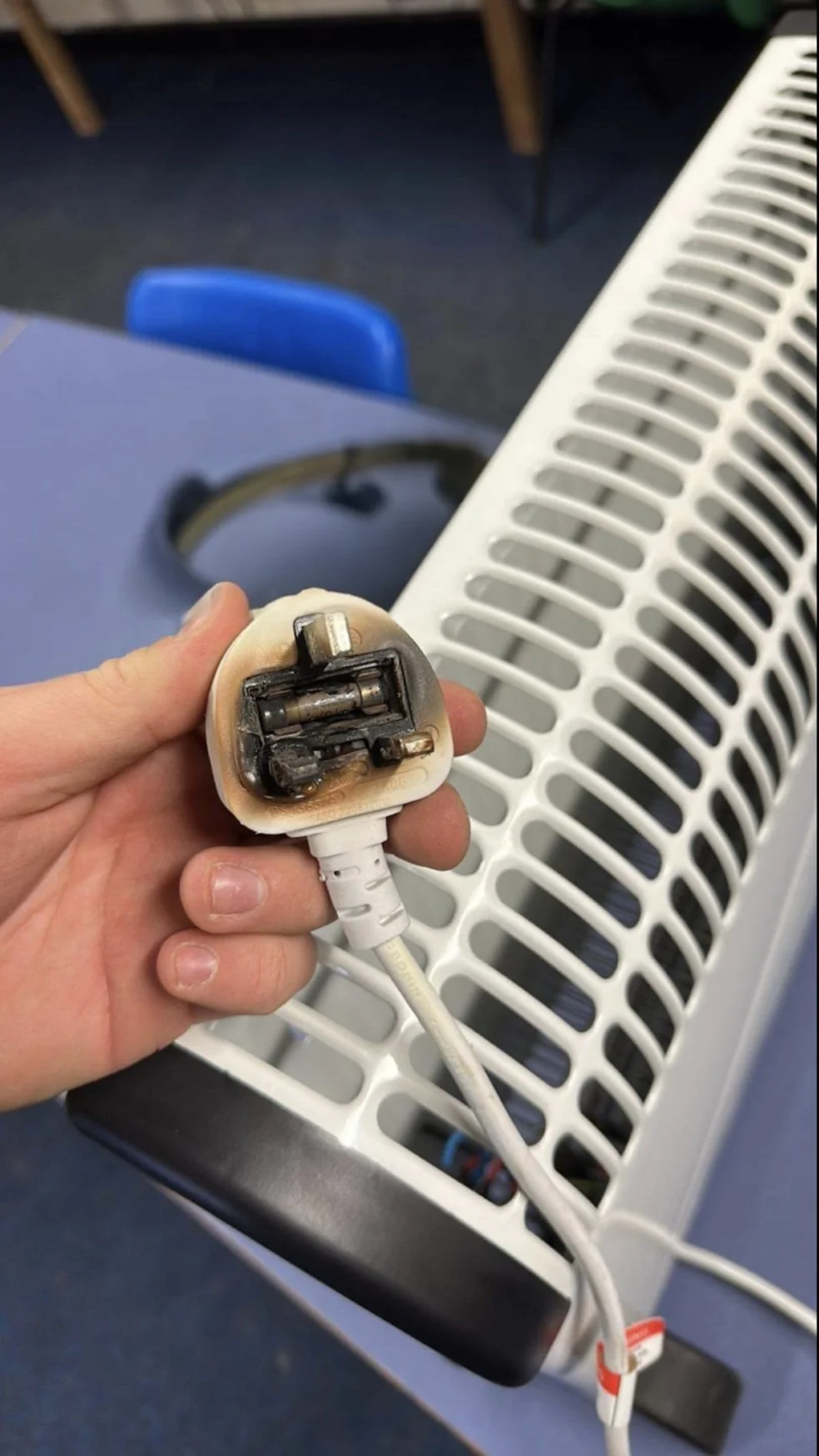

Appliances we have reported to the duty holder and removed from service.

Floor standing heater which had a melted plug, burnt fuse and pins from overheating.

Extension lead with a melted socket not only was the extension lead melted the appliance which we unplugged also had burnt pins and a melted plug.

Another kettle found meted into the socket at the end of tenancy checkout from a landlords property.

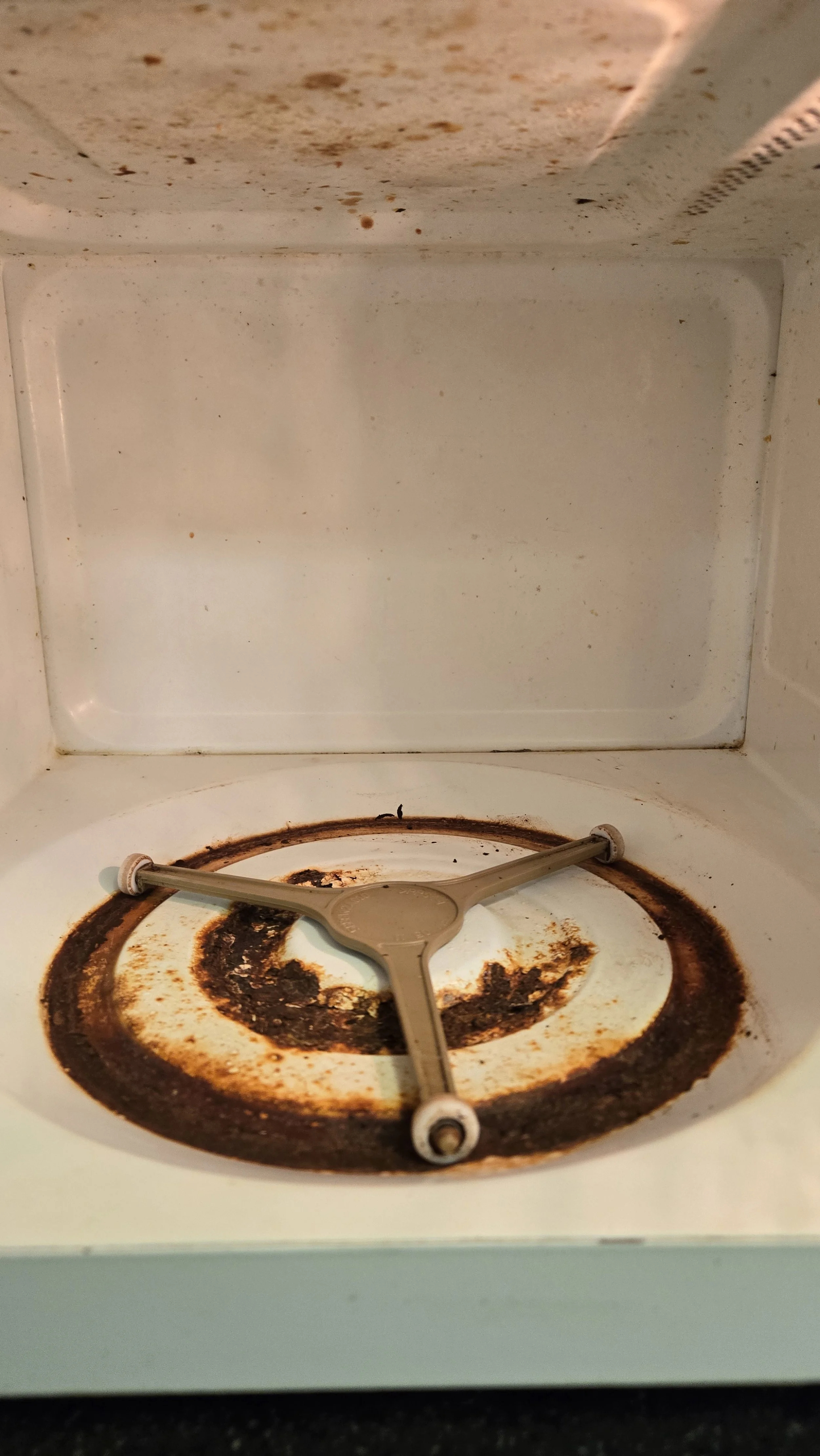

The Importance of a Formal Visual Inspection

A formal visual inspection plays a critical role in ensuring the safety and reliability of electrical appliances. In fact, all the appliances listed below were unable to successfully pass the rigorous standards set forth during the formal visual inspection process. This highlights the essential need for thorough evaluations to identify potential hazards and to maintain a safe environment for users.

Another fail without being tested. Visual inspections and regular user checks could of found this fault before the annual PAT test.

Another microwave failed its formal visual inspection and withdrawn from service.

Exposed wires on a power lead we always make sure to do a full flex check from plug to the appliance.